Ukucubungula kwe-SMT kuyinqubo eyinkimbinkimbi ehlanganisa izinyathelo eziningi zokucubungula, abanye onjiniyela bangase bazidayisele izingxenye ze-SMD ngokwabo, kodwa ngizokutshela ukuthi kungani kufanele kusingathwe ochwepheshe abaqeqeshiwe kuphela.

Okokuqala, yini i-SMT welding processing?

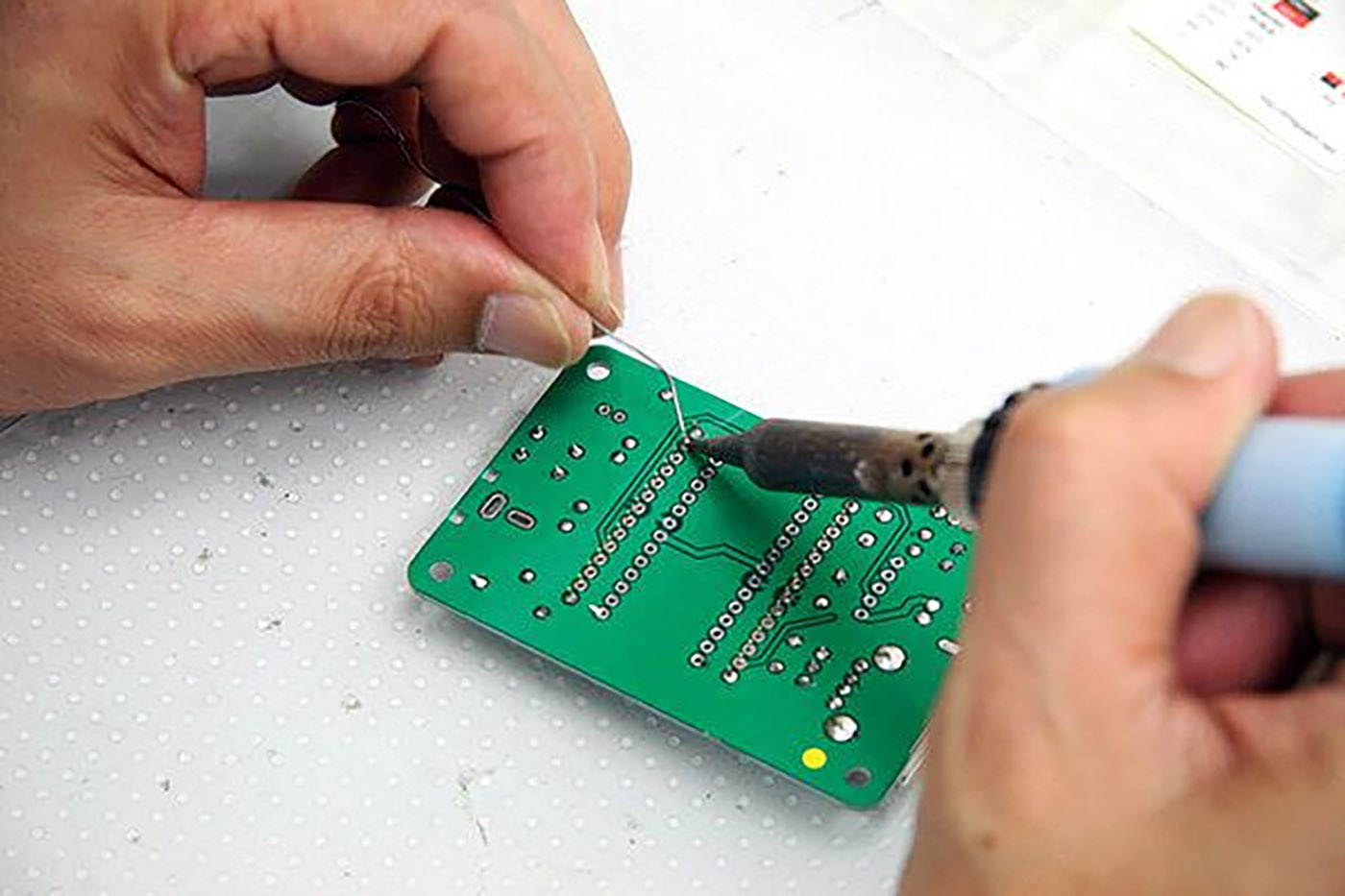

Lapho kuhlanganiswa izingxenye ze-PCB, kunobuchwepheshe obubili obuyinhloko, nge-Hole Technology (THT) kanye ne-Surface Mount Technology (SMT).I-THT yayisetshenziswa kakhulu kumasekethe amadala angenayo i-SMT, futhi manje isisetshenziswa kuphela kumasekethe angafundile nabangafundile.Inqubo yokumboza ngembobo ihlanganisa izimbobo zokubhoboza ku-PCB, ukukhweza izingxenye ze-elekthronikhi ku-PCB, kanye nokunamathisela ingxenye kuholela ezintanjeni zethusi ngakolunye uhlangothi lwebhodi.Le nqubo yokushisela iyabiza, ihamba kancane, inzima futhi ayikwazi ukuzenzela.Ngaphezu kwalokho, izingxenye ezinamatheminali okuhola zivame ukuba yinqwaba, zizenze zingafaneleki amasekhethi esimanje kagesi anezidingo zesici esibalulekile sefomu.

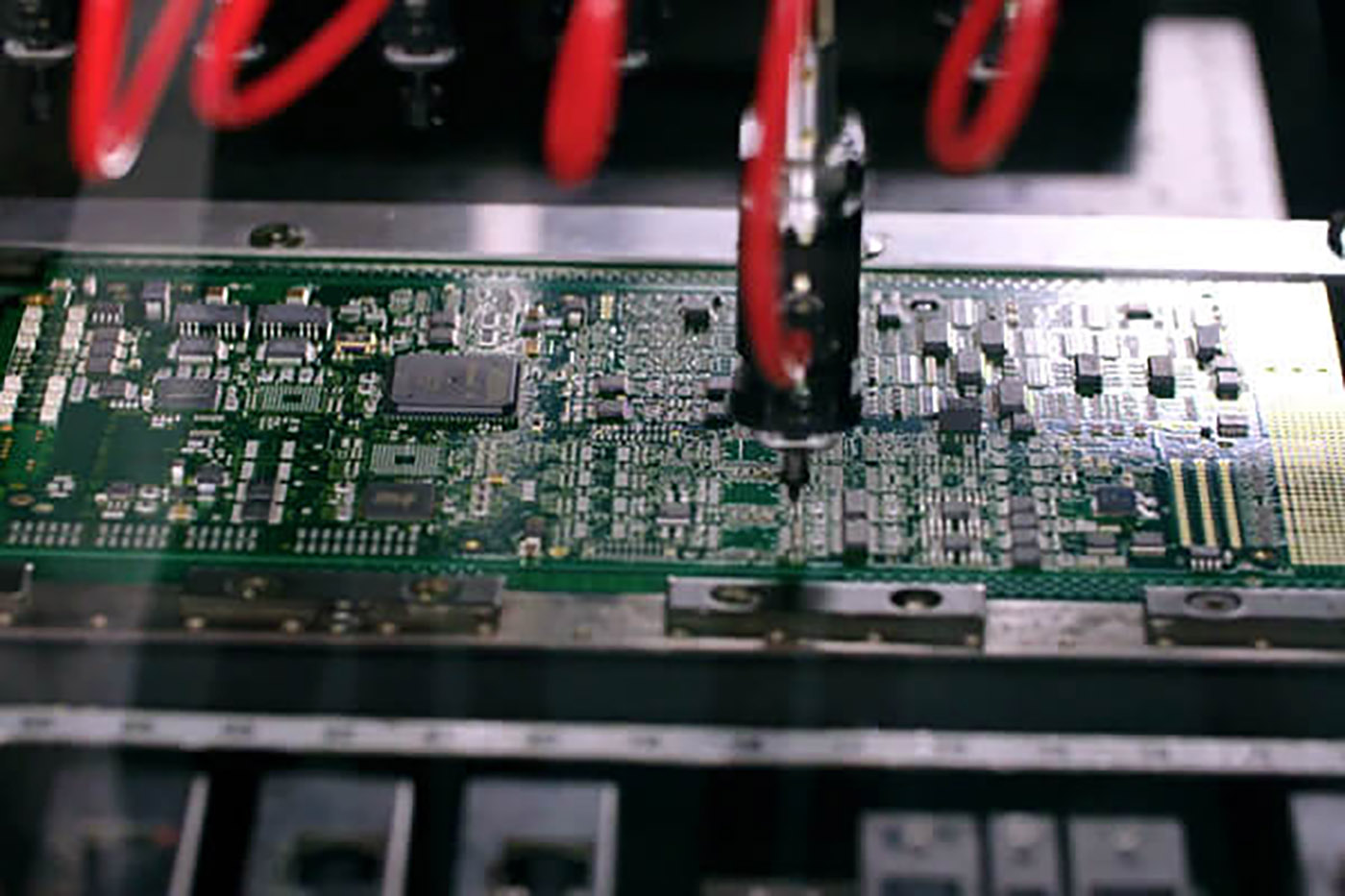

Namuhla, ukucutshungulwa kwe-SMT sekucishe kwathatha indawo yezindlela zokunamathisela ezivamile ekukhiqizeni i-PCB.Ku-SMT soldering, izingxenye zibekwe ngqo ebusweni be-PCB kunokuba ngokubhoboza.I-Surface Mount Devices ( SMD ) inonyawo oluncane kakhulu kunezingxenye ze-THT ezivamile.Ngalesi sizathu, inani elikhulu lezingxenye ze-SMD lingapakishwa endaweni encane, linikeze amandla imiklamo yesekethe ye-elekthronikhi ehlangene kakhulu futhi eyinkimbinkimbi.Enye inzuzo enkulu ye-soldering yengxenye ye-SMT ukuthi inqubo ingenziwa ngokuzenzakalelayo, ikhulise ukunemba, isivinini, ukusebenza kahle kanye nokusebenza kahle kwezindleko.Namuhla, i-SMT soldering manje isiyindlela yokuhlanganisa ye-PCB ezenzakalelayo.

Kungani ukucubungula kwe-SMT kufanele kudluliselwe enkampanini yochwepheshe?

Akungabazeki ukuthi ukudayiswa kwengxenye ye-SMT kunezinzuzo eziningi, kodwa inqubo ikude nokulula.Eqinisweni, ukudayiswa kwe-SMT okuphrofeshinali kuyinqubo eyinkimbinkimbi ehlanganisa izinyathelo eziningi zenqubo.Uma kubhekwa inkimbinkimbi yenqubo kanye nezinga lobuchwepheshe elidingekayo, umsebenzi wokuthelisa we-SMT kumele wenziwe ngochwepheshe abaqeqeshiwe.

• Amathuluzi akhethekile nemishini

• Ukuthengwa kwempahla

• amakhono nolwazi

Amathuluzi nemishini edingekayo ukuze i-SMT soldering ivamise ukubiza kakhulu.Kungaba nzima kumuntu osemusha ukuthi amise ilabhorethri efanele enawo wonke amathuluzi adingekayo nemishini njengoba kungabiza imali eshisiwe.Kodwa-ke, inkampani ephrofeshinali ye-SMT efana ne-Pinnacle inokusetha okufanele kwayo yonke imishini edingekayo.Ngakho-ke, ukukhipha i-SMT kungenza ukuhamba komsebenzi kube lula, kuqondile futhi kungabizi kakhulu.

Ngaphezu kokuhlinzeka ngamathuluzi nemishini, ukwazi nokwazi kubaluleke ngendlela efanayo.Imishini ayinamsebenzi ngaphandle kobuchwepheshe obufanele.I-SMT soldering iyinqubo eyinkimbinkimbi edinga ukuzinikela nokuzijwayeza ukuze ukwazi kahle.Ngakho-ke, kuphumelela kakhulu ukushiya umsebenzi wokuhlanganisa kochwepheshe kunokuba uzenzele kabusha isondo.Ukwengeza, izinkampani ezinobuchwepheshe bokuthengisa be-SMT nazo zisebenza ngokukhethekile ekutholeni izingxenye, ezivumela ukuthi zithole izingxenye ngokushesha futhi ezishibhile.

Imakethe yokudayiswa kwengxenye ye-SMT yayilinganiselwa ku-USD 3.24 billion ngo-2016 futhi kulindeleke ukuthi ikhule ngo-8.9% phakathi kuka-2017-2022.Imakethe ye-SMT iyimakethe enkulu enezigaba eziningi zemakethe.Izithameli eziqondiwe zihlanganisa abaklami be-IC, ama-OEM, abakhiqizi bemikhiqizo, izikhungo ze-R&D, abahlanganisi bohlelo kanye namafemu okubonisana.

Ngenxa yokuthi amabhodi esekethe aphrintiwe anembayo asetshenziswa kuzo zonke izigaba zokuphila, ayikho inkambu engahlobene nobuchwepheshe be-SMT.Izindawo okugxilwe kuzo zihlanganisa ama-electronics omthengi, ezokuxhumana, i-aerospace nokuvikela, ezezimoto, ama-electronics ezokwelapha nezimboni.

Isikhathi sokuthumela: Mar-29-2023