Ukuhlanganiswa kwe-PCBkuyinqubo ebalulekile ekwenziweni kwemishini kagesi.Ukuhlanganiswa okufanele kwamabhodi esekethe aphrintiwe (ama-PCB) kuqinisekisa ukusebenza nokuthembeka kwemishini kagesi.Kulokhu okuthunyelwe kwebhulogi, sizocubungula izisekelo zokuhlangana kwe-PCB, sixoxe ngokubaluleka kwayo, futhi sigqamise izinzuzo zezinsizakalo zokuhlangana ezichwepheshile.

Funda mayelana nokuhlanganiswa kwe-PCB.

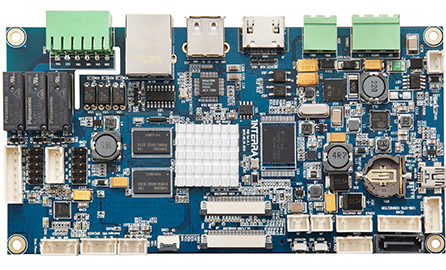

Ukuhlanganiswa kwe-PCB kuhilela inqubo yokukhweza izingxenye ze-elekthronikhi ku-PCB engenalutho.Kuhlanganisa izindlela ezimbili eziyinhloko: ubuchwepheshe be- through-hole (THT) kanye nobuchwepheshe bokukhweza komhlaba (SMT).Ubuchwepheshe be- through-hole buhilela ukufaka umkhondo emigodini ku-PCB, kuyilapho ubuchwepheshe bokukhweza phezulu buhlanganisa izingxenye zokunamathisela ngqo ebusweni bebhodi lesifunda.

Ukubaluleka komhlangano we-PCB ofanele.

1. Ukusebenza: I-PCB ehlanganiswe kahle iqinisekisa ukusebenza okuvamile kwemishini kagesi.Ukuhlanganiswa okungalungile kungabangela ukwehluleka kwe-PCB, amasekhethi amafushane, noma ngisho nokwehluleka okuphelele, okuholela ekulungiseni okubizayo noma ekushintshweni.

2. Ukuthembeka: Umhlangano wekhwalithi ephezulu uqinisekisa ukwethembeka kwemishini ye-elekthronikhi futhi unciphisa ingozi yokwehluleka ngesikhathi sokusebenza okubalulekile.Amasu okunamathisela afanelekile angavimbela ukuxhumana okungalungile futhi aqinisekise ukuzinza, ukugwema izinkinga zesikhashana.

3. I-Miniaturization: Ama-PCB aba mancane futhi ayinkimbinkimbi, futhi ukuhlanganisa okwenziwa ngesandla akusafezeki ngobuchwepheshe obuthuthukisiwe.Izinsizakalo zokuhlanganisa ze-PCB zisebenzisa okokusebenza okuzenzakalelayo njengemishini yokukhetha nendawo ukubeka izinto ngokunembile, ngisho nasemabhodini esekethe amancane naminyene.

4. Ukusebenza Kwesikhathi: Izinsizakalo zomhlangano ezichwepheshile zinolwazi, isipiliyoni, kanye nemishini ekhethekile yokuhlela inqubo yomhlangano, ngaleyo ndlela kuncishiswe isikhathi sokukhiqiza.Lokhu kuqinisekisa ukuguqulwa okusheshayo futhi kwenza abakhiqizi bakwazi ukuhlangabezana nezidingo zemakethe kanye nezinsuku zokugcina ngokuyimpumelelo.

Izinzuzo zezinsizakalo zomhlangano we-PCB ochwepheshe.

1. Ulwazi lobungcweti: Izinsizakalo zokuhlanganisa ezichwepheshile ziqasha ochwepheshe abanekhono abachwepheshile kubuchwepheshe bokuhlanganisa i-PCB, baqonde amazinga akamuva embonini, futhi baqonde izinhlobo zezingxenye ezihlukahlukene.Ubuchwepheshe babo buqinisekisa ukubekwa okunembile, ukusoda okulungile, nokuhlolwa okulungile kwama-PCB ahlanganisiwe.

2. Amathuluzi: Izinsizakalo zokuhlanganisa ezichwepheshile zitshala imali emishinini yesimanje njengamaphrinta e-stencil, izithando zomlilo, nemishini yokuhlanganisa ezenzakalelayo.Lawa mathuluzi athuthukile aqinisekisa ukubekwa kwengxenye okunembayo, ukusoda okufanayo, nokuhlolwa okuphelele ukuze kukhiqizwe ama-PCB ekhwalithi ephezulu.

3. Ukulawulwa kwekhwalithi: Izinsizakalo zokuhlanganisa ezichwepheshile zinamathela ezinyathelweni eziqinile zokulawula ikhwalithi ukuze kuqinisekiswe ukwethembeka nokusebenza kwama-PCB ahlanganisiwe.Balandela izindinganiso zomkhakha, benze ukuhlola okuphelele, futhi basebenzise izindlela zokuhlola ezithuthukisiwe ezifana ne-Automated Optical Inspection (AOI) ukuze bathole noma imaphi amaphutha futhi bawalungise ngokushesha.

4. Ukusebenza Kwezindleko: Nakuba ukuhlanganiswa kwe-PCB kwangaphandle kungase kubonakale kubiza, kubonakala kuyisixazululo esingabizi ngokuhamba kwesikhathi.Izinsizakalo zokuhlangana ezichwepheshile ziqeda isidingo semishini ebizayo, ukuqeqeshwa kanye nomsebenzi.Ukwengeza, amaphutha e-PCB ancishisiwe kanye nokuphumayo kwekhwalithi ephezulu kunomthelela ekongeni kwezindleko kukonke.

Ukufingqa, ukuhlanganiswa kwe-PCB kudlala indima ebalulekile enqubweni yokukhiqiza imishini kagesi.Ukukhetha izinsizakalo zomhlangano ochwepheshe kuqinisekisa ukusebenza, ukwethembeka kanye nokusebenza kahle kwezindleko.Ukusebenza nochwepheshe kulo mkhakha kusindisa isikhathi, kuqeda amaphutha, futhi kuqinisekisa ama-PCB ekhwalithi ephezulu, ekugcineni kuzuzise abakhiqizi nabasebenzisi bokugcina.Ngakho-ke, uma udinga ukuhlanganiswa kwe-PCB, cabanga ngezinzuzo nobungcweti bezinsizakalo zochwepheshe ukuze uthole imiphumela engcono kakhulu.

Isikhathi sokuthumela: Sep-06-2023