Ezinkampanini eziningi zemikhiqizo ye-elekthronikhi emincane namaphakathi, ukukhishwa kwe-PCB patch processing kuyinto evamile.Kodwa ngokuvamile, izitshalo eziningi zokukhiqiza eziphuma ngaphandle ngeke zikwenzele yonke into, noma azikwazi ukufaka esikhundleni samakhasimende ukuze zithuthukise ezinye izinto, njengokuguquguquka kwebhodi nomkhiqizo, ukuqonda kokuklama, ukuguquguquka kwengxenye, njll.

Uma ukuthengwa kwempahla noma onjiniyela bebhizinisi bengenza lezi zinto ezilandelayo eziyi-8 kahle ngaphambi kokuphonsa izidingo nezinto zokukhiqiza efektri ye-PCB yokucubungula iziqephu, eziningi zezinkinga okuhlangatshezwane nazo ekukhiqizeni nasekukhiqizeni kamuva zingagwenywa.

1. Thola usayizi we-PCB ongcono kakhulu womklamo wakho

Ngokukhiqizwa kwe-PCB, amabhodi amancane ngokuvamile asho izindleko eziphansi, kodwa umklamo ungase udinge izendlalelo zangaphakathi ezengeziwe, ezizokwandisa izindleko zakho.Amabhodi amakhulu azoba lula ukuwenza futhi ngeke adinge izendlalelo zesignali ezengeziwe, kodwa azobiza kakhulu ukuwakha.Okokuqala, kufanele ucabangele indlela yokubala usayizi ofaneleka kakhulu ngaphandle kokulahlekelwa izici.

2. Cacisa usayizi wengxenye

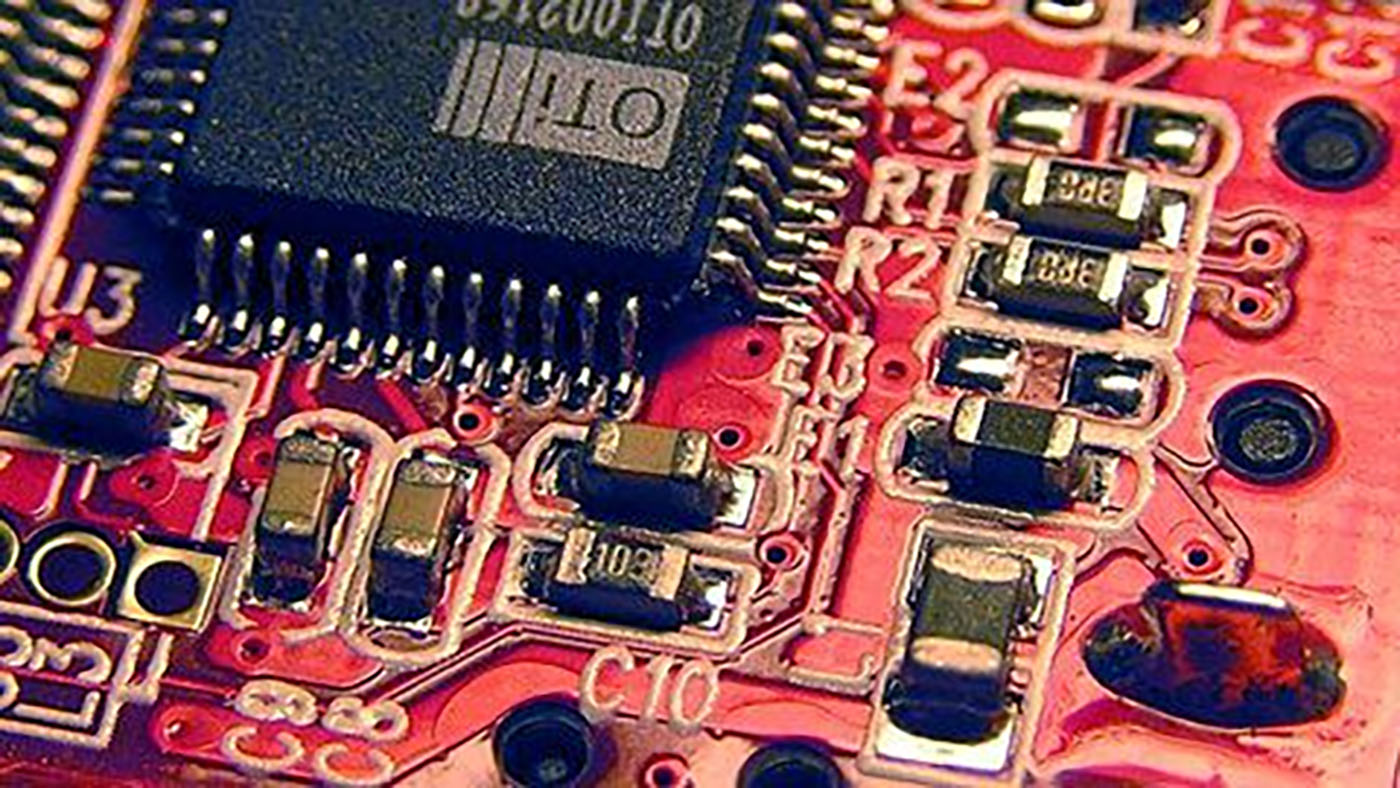

Ukukhipha i-PCB patch processing.jpg

Ezingxenyeni ze-passive, usayizi ojwayelekile we-0603 ungaba ukukhetha okungcono kakhulu kwezindleko eziphansi, okubuye kube usayizi ojwayelekile futhi ovumela ukuhlanganiswa kwe-SMT.Amadivayisi we-0603 nawo alula ukuwahambisa nokusebenza, futhi awabi isithiyo njengamadivayisi amancane kakhulu.

Ngenkathi u-Pinho ekwazi ukucubungula amadivayisi anosayizi ongu-01005, akubona bonke abahlanganisi abangakwenza, futhi izingxenye ezincane azibalulekile.

3. Hlola izingxenye eziphelelwe yisikhathi noma ezintsha kakhulu

Izingxenye eziphelelwe yisikhathi ngokusobala azisasebenzi, lokho ngeke kukuvimbe ekwenzeni i-PCBA, kodwa izobambeka enqubweni yokuhlanganisa.Namuhla, nokho, ezinye izingxenye ezintsha zitholakala kuphela nge-wafer ultra-miniature BGA noma osayizi abancane be-QFN.Bheka idizayini yakho ye-PCBA futhi uqiniseke ukuthi ushintshe noma yiziphi izingxenye eziphelelwe yisikhathi ufake ezintsha ezingcono.

Enye inothi ukukhumbula ama-MLCC owasebenzisayo, manje adinga umjikelezo omude wokuthenga.

Manje sinikeza amakhasimende ukuhlaziywa kwe-BOM okubheke phambili, xhumana nathi ukuze ufunde ukuthi ingakusiza kanjani ukugwema izingozi futhi wehlise isabelomali ngezinga elikhulu kakhulu.

4. Cabangela ezinye izindlela

Okunye njalo kuwumqondo omuhle, ikakhulukazi uma usuvele usebenzisa ezinye izingxenye zomthombo owodwa.Ukuthola usizo olulodwa kusho ukuthi ulahlekelwa ukulawula izintengo nezikhathi zokulethwa, ezinye izindlela zizokusiza ukugweme lokho.

5. Ungakhohlwa ukukhipha ukushisa lapho wenza amabhodi esekethe aphrintiwe

Izingxenye ezinkulu kakhulu nezingxenye ezincane kakhulu zingabangela izinkinga.Ingxenye enkulu isebenza kancane njengesitha sokushisa futhi ingalimaza ingxenye encane.Okufanayo kungenzeka uma i-foil yethusi yangaphakathi idlula ingxenye eyodwa yengxenye encane kodwa hhayi enye ingxenye.

6. Qiniseka ukuthi inombolo yengxenye kanye nezimpawu ze-polarity ziyafundeka

Qinisekisa ukuthi kucacile ukuthi yisiphi isikrini sikasilika esihambisana nanoma iyiphi ingxenye, nokuthi izimpawu ze-polarity azihlanganisi.Naka ngokukhethekile izingxenye ze-LED ngoba abakhiqizi ngezinye izikhathi bashintsha izimpawu ze-polarity phakathi kwe-anode ne-cathode.Futhi, gcina izimpawu kude ne-vias nanoma imaphi amaphedi.

7. Hlola inguqulo yefayela

Kuzoba nezinguqulo eziningi zesikhashana zomklamo we-PCB noma i-BOM, vele wenze isiqiniseko sokuthi lezo osithumelela zona ukuze kwenziwe i-PCB ziyizibuyekezo zokugcina.

8. Uma izingxenye ezithile zizohlinzekwa

Sicela uqinisekise ukuthi uwafake ilebula futhi wawapakisha ngendlela efanele, okuhlanganisa nenani nengxenye ehambisanayo nenombolo.Ulwazi oluningiliziwe olunikeziwe luzosiza abakhiqizi ukuthi baqedele ukwakhiwa nokuhlanganisa amabhodi esekethe aphrintiwe ngokushesha.

Isikhathi sokuthumela: Mar-29-2023